The Company

S.r.f. specializes in the machining of plastic and metal materials, providing tailor-made solutions for a variety of industrial applications. Thanks to a structured production process and advanced technologies, we ensure precision, reliability, and optimized delivery times.

From design to production, every stage is carefully managed to maintain high quality standards, supported by a well-stocked semi-finished materials warehouse and a cutting-edge metrology department.

SEMI-FINISHED MATERIALS WAREHOUSE

S.r.f. relies on a well-stocked inventory of semi-finished materials, ready for immediate use based on customer needs.

Materials available in sheet and rod form:

- PE 500

- PE 1000

- PVC PA6

- PA6 MOS

- POM

- PET

- PET-TX

- PTFE

- PMMA

- POLYCARBONATE

- PVDF

- PEEK

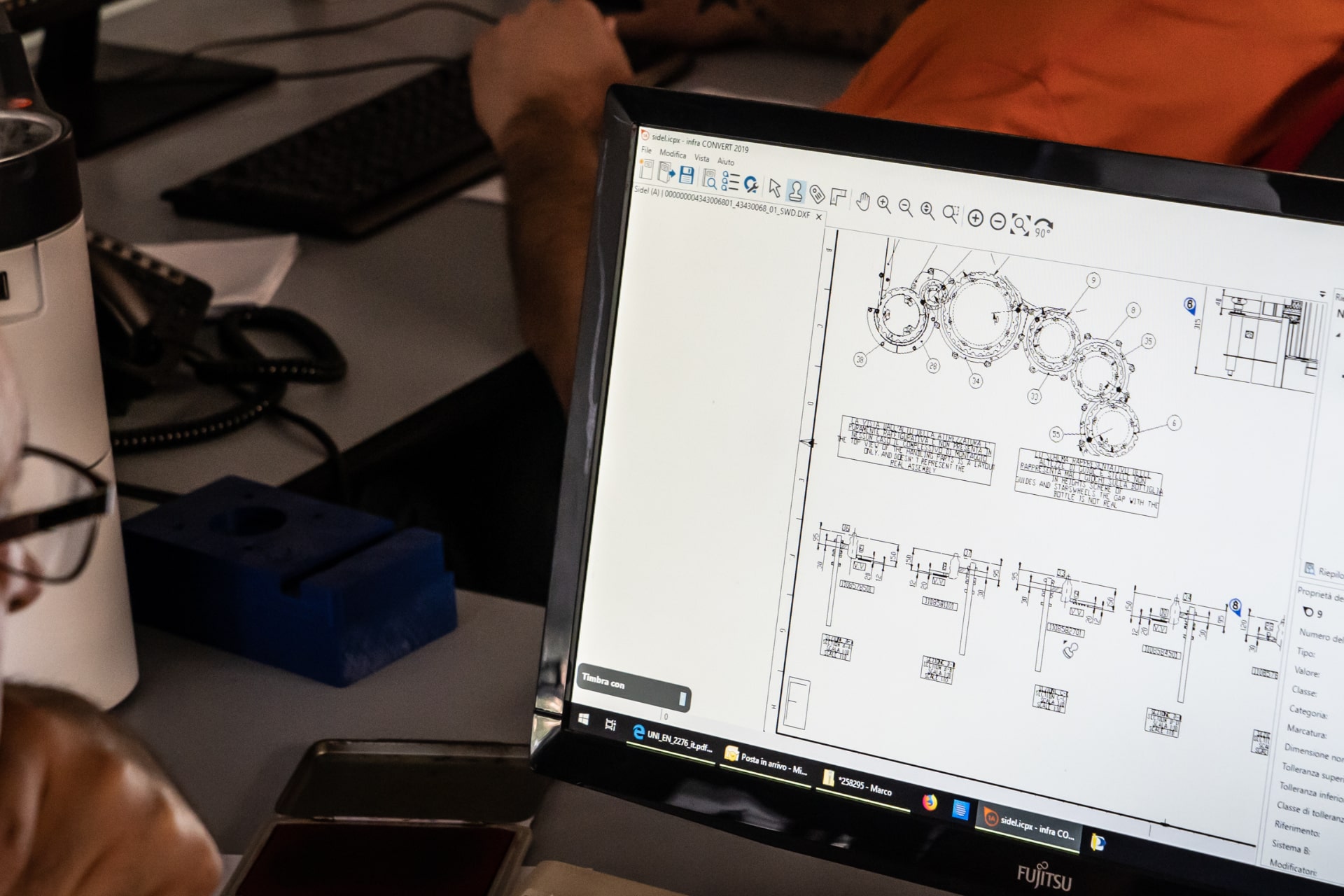

TECHNICAL OFFICE

– PROGRAMMING

Once the production orders are processed by the Production Planning Manager, they are handed over to the Technical Office.

Here, with the support of advanced software and highly skilled personnel, the customer’s drawing is converted into a 2D or 3D model, translated into machine code, and sent to production.

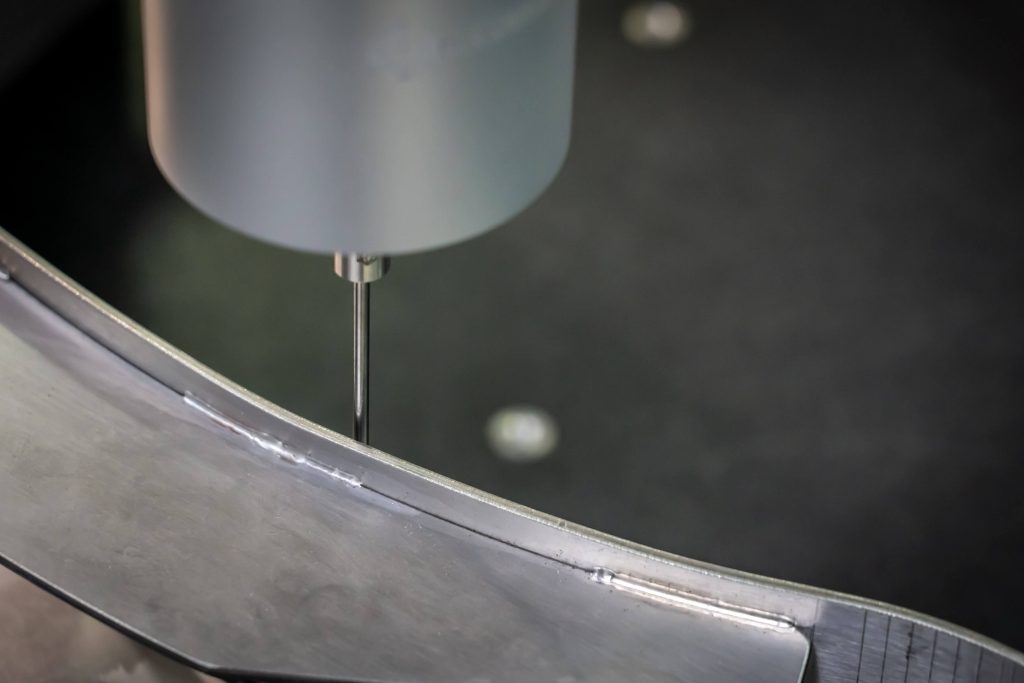

METROLOGY ROOM

For more complex measurements, and when a certification or full inspection report is required, S.r.f. operates a dedicated metrology room equipped with a Hexagon CMM with a measuring range of 1500 x 900 x 620 mm.

S.r.f. also uses a laser spectrometer for metal analysis.

All parts are marked using micro-percussion (on plastic and steel), laser technology (for plastics), or electrolytic marking (for stainless steel).