AIRPORT BHS

(Baggage Handling System)

S.r.f. has developed an innovative solution specifically designed for baggage claim conveyor belts.

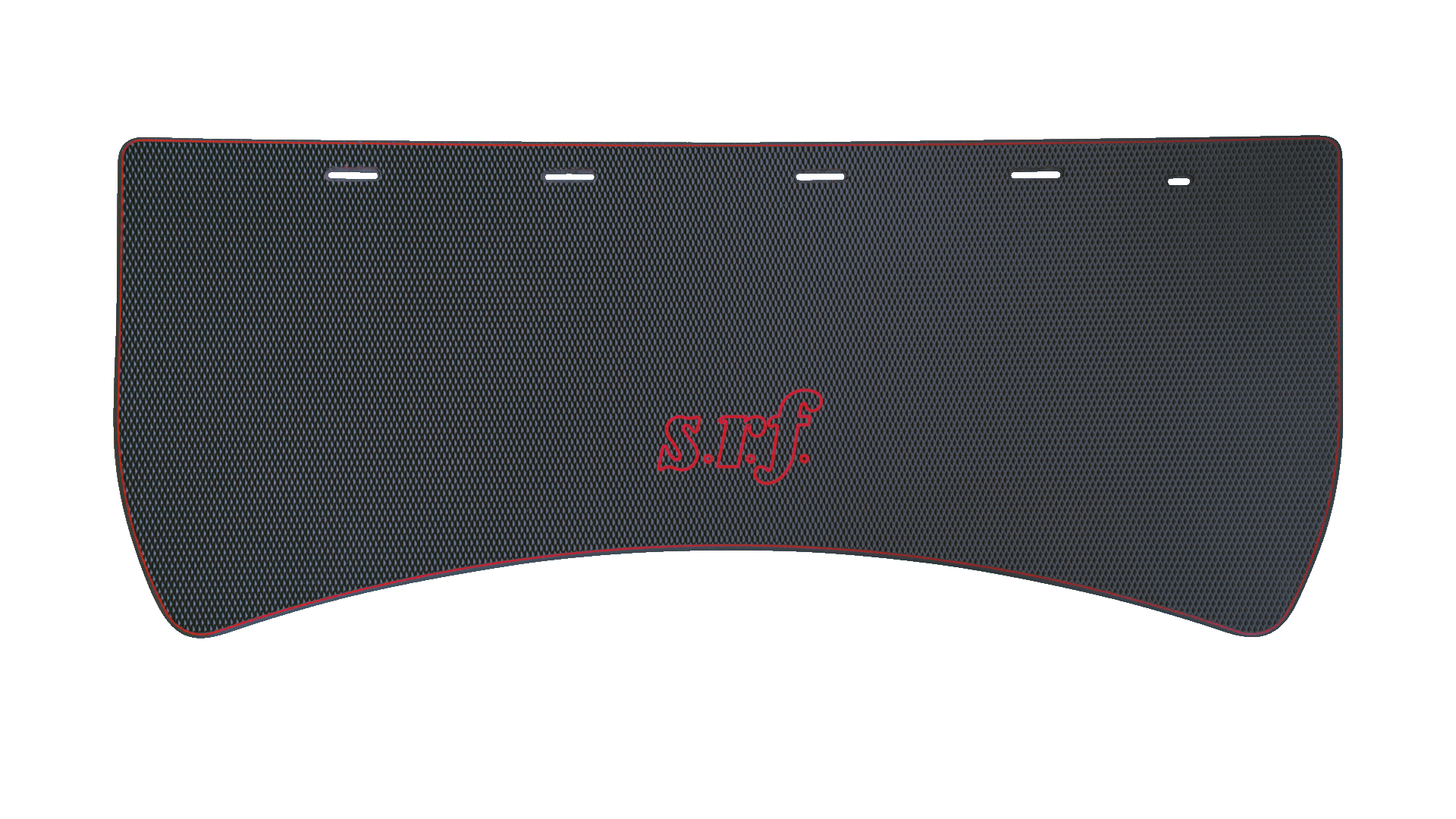

NEO BELT B™ plates, made from pressed PVC, are entirely manufactured in-house at S.r.f.’s pressing department.

The result is a product with a rigid surface that remains flexible enough to bend almost completely—and quickly return to a perfectly flat position.

This unique balance of stiffness and elasticity, combined with a scratch-resistant surface, makes NEO BELT B™ a cutting-edge solution for efficient baggage management in airport environments.

NEO BELT B™

Thanks to its customizable hardness levels, NEO BELT B™ overcomes the common issues of stiffness and deformation typically found in extruded or injection-molded plates.

Born from decades of experience at S.r.f., this revolutionary product is manufactured using V0-rated self-extinguishing materials and complies with the most stringent safety standards for airport equipment.

STRONGER, MORE FLEXIBLE

The use of plates with varying hardness and plasticity gives NEO BELT B™ several practical advantages over similar products.

The outer layer, being more rigid, resists impact and scratching caused by luggage.

The inner layer, being softer, ensures flexibility and structural stability.

Currently, there is nothing on the market with comparable specs in terms of durability, versatility, and the ability to return to its original shape after stress or deformation.

STABILITY ON INCLINES

For inclined baggage conveyors, S.r.f. has developed NEO BELT-GRIP, a variant made from high-grip material. Its enhanced surface adhesion prevents luggage slippage even on steep inclines, ensuring reliable handling.

A BOLD CHOICE

The plates can be personalized with engraved text or logos, based on client specifications—available in tone-on-tone black or with contrasting colors for added visibility.

ANTISTATIC SOLUTION

In addition to flame-retardant properties, we offer an optional antistatic feature to neutralize localized electric charges.

NEO BELT ADVERTISING

Thanks to its variable hardness, NEO BELT B™ solves the typical rigidity and deformation problems found in extruded or molded plates.

This patented product—developed through decades of expertise—is made from V0-rated self-extinguishing materials and fully meets the strictest airport safety regulations.

GUARANTEED DURABILITY

Unlike surface-printed plates that wear over time, NEO BELT ADVERTISING ensures long-lasting ad visibility with a patented internal display system.

Its quick-release mechanism allows for easy and effortless graphic replacement at any time.

MAXIMUM FLEXIBILITY FOR AD SPACE MANAGEMENT

The versatility of NEO BELT ADVERTISING allows the conveyor to be divided into multiple segments, each with a different graphic—maximizing advertising opportunities.

Choosing NEO BELT ADVERTISING means unlocking new and original ways to boost revenue, reliably and efficiently.