PRODUCTION

S.r.f. offers a wide range of machining services on plastic and metal materials, ensuring precision, quality, and tailor-made solutions for every need. Thanks to state-of-the-art machinery and a specialized technical office, we are able to perform milling, turning, custom auger production, and complex assembly operations.

MILLING

S.r.f. performs plastic milling using vacuum table pantographs, starting from standard dimensions up to 5000 x 2500 mm.

For more precise components in plastic or steel, CNC machining centers are used to achieve high accuracy.

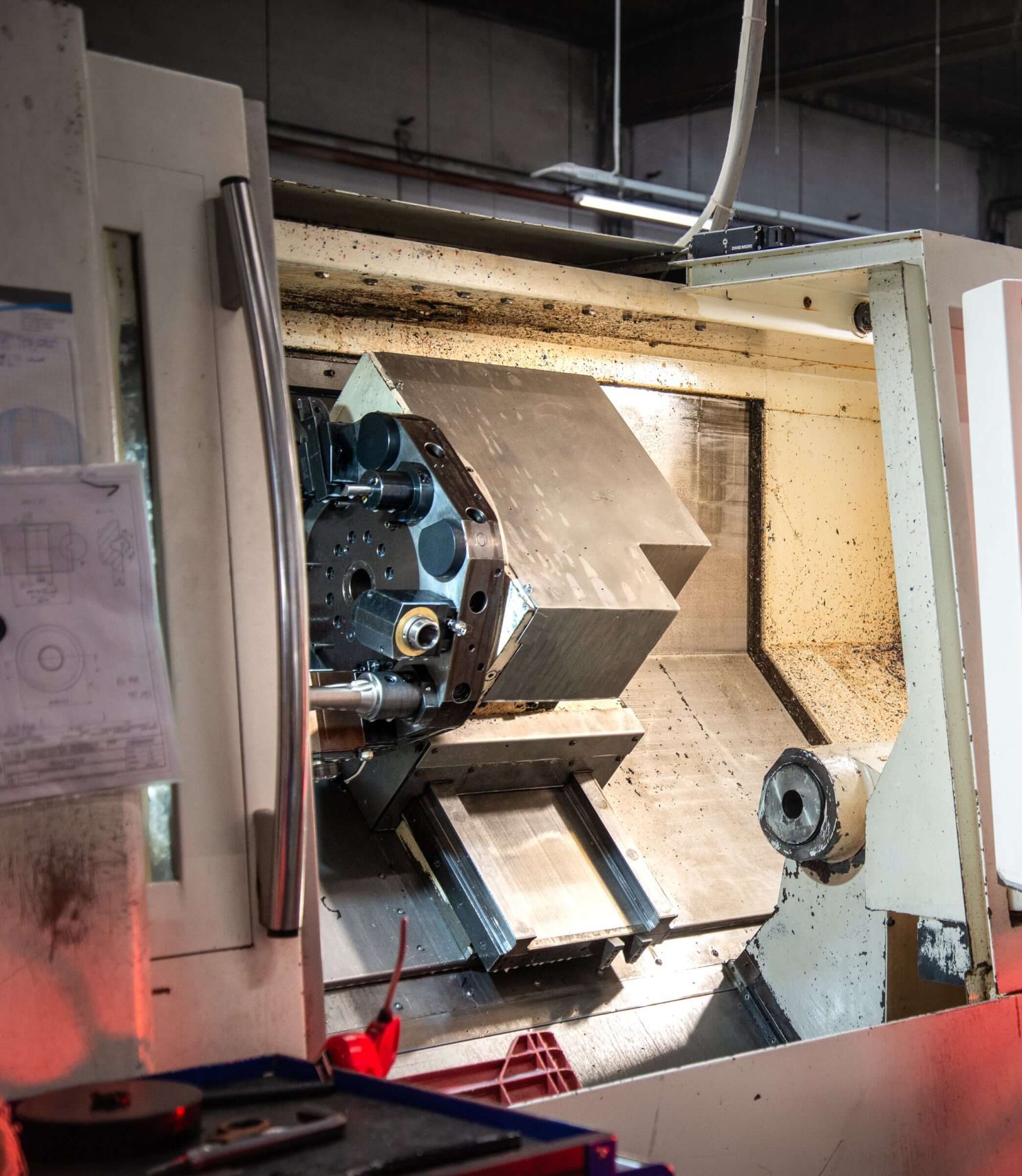

TURNING

The turning department is equipped with 3- and 4-axis CNC lathes, fitted with powered tools and machines featuring sub-spindles.

S.r.f. is able to meet the needs of even the most demanding clients, providing material certifications and stringent quality controls.

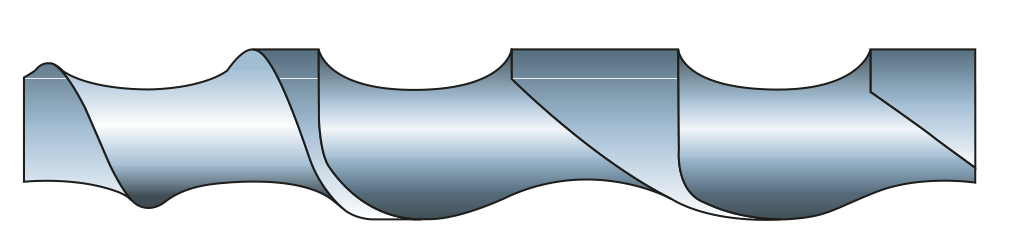

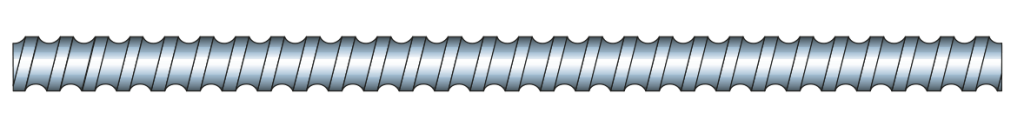

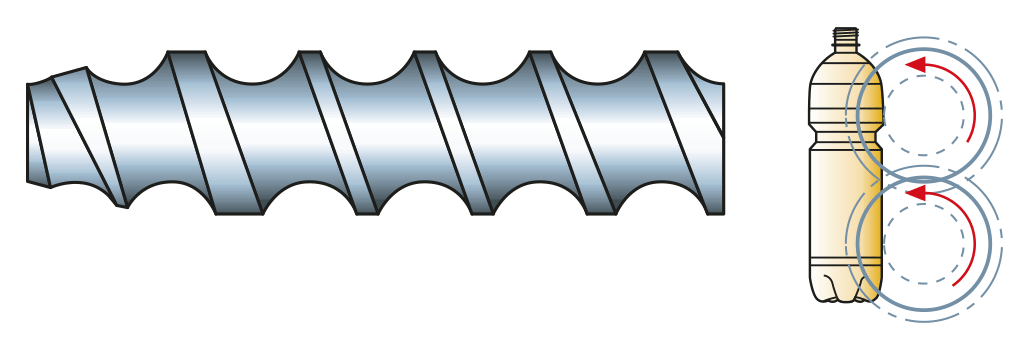

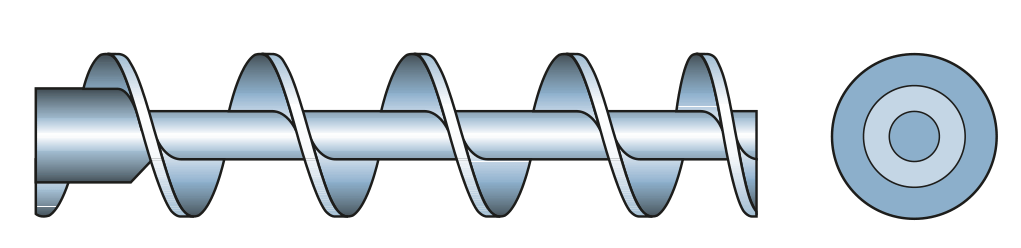

AUGERS

Thanks to its in-house technical office, S.r.f. develops and assesses the feasibility of augers, providing clients with design simulations.

Augers can be manufactured from a range of plastic materials and supported by stainless steel shafts—entirely produced in-house.

Zero-pitch augers

Transfer augers

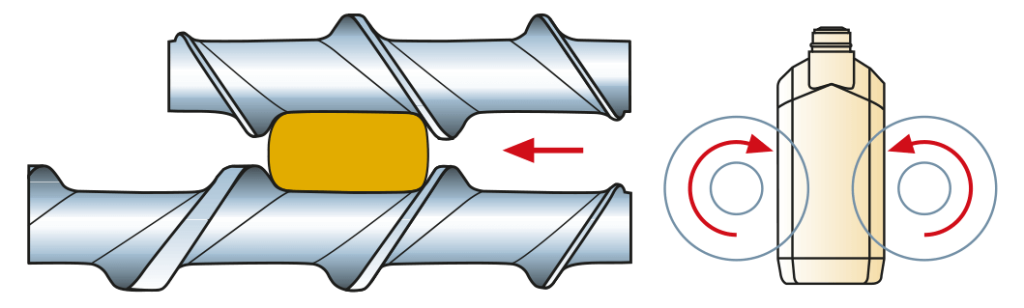

Neck-handling augers

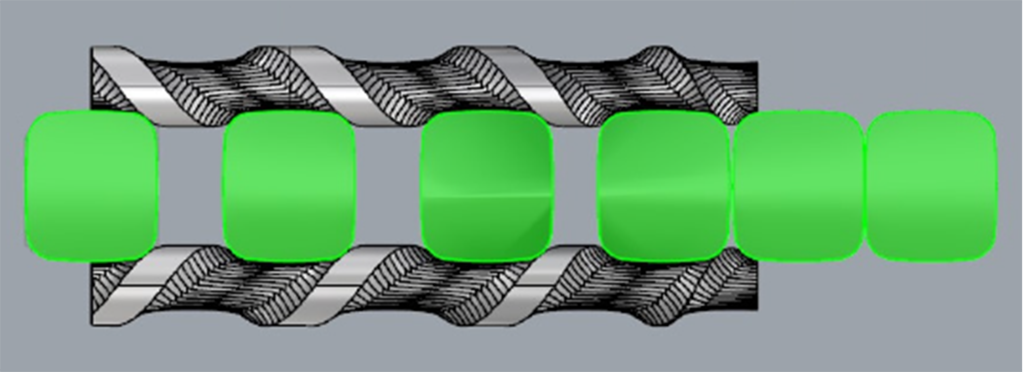

Twin augers (overlapping)

Twin augers (counter-rotating)

Bottle-guiding augers

Powder dosing and feeding augers

ADDITIONAL OPERATIONS & ASSEMBLY

S.r.f. has a dedicated and fully independent area for the assembly of mechanical units, physically separated from the main production area. This department exclusively receives inspected parts from the internal Quality Control division.

In addition to traditional machining, S.r.f. also operates a manual polishing area for mirror-finish components.

External partners are involved only for electropolishing processes.